Solutions for sustainable additive manufacturing

We provide our clients with expertise in startup and development of production using AM.

Starting with delivery of AM Systems through manufacturing & quality process development ending with continuous support and providence of tailor-made metal powders.

Our core focus

TitAnium from recycling

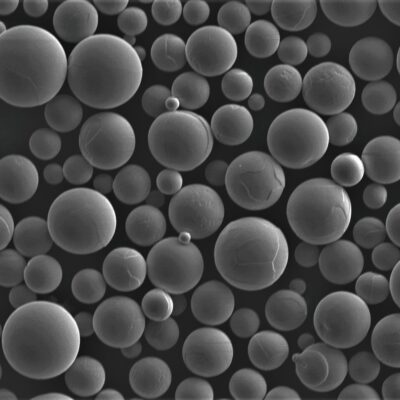

Made 100% From recycling, in EU, Spherical 15 – 63 um

The EU has a strong position in AM, and especially in metal-based additive manufacturing for aerospace applications. At the same time, a high raw materials dependency exists, in particular for titanium. That is why we have developed a technology for production of titanium alloys powders using production waste, such as chips from machining processes.

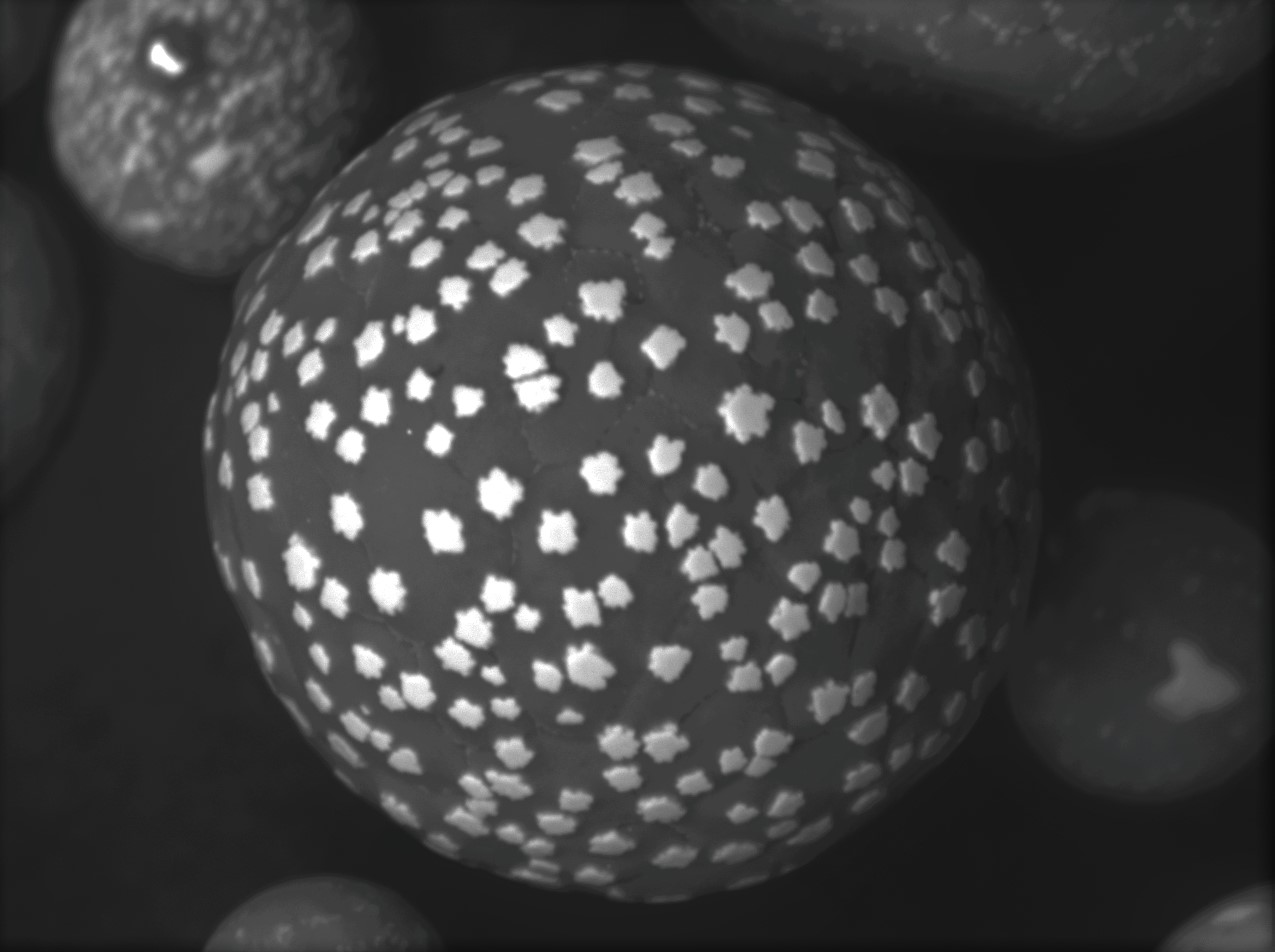

Composite

powders

Printable

AW7075 & AW7050

We are developing a modified aluminium alloys powders that not only allow for their printing without hot cracking phenomenon, but also improve their heat resistance.

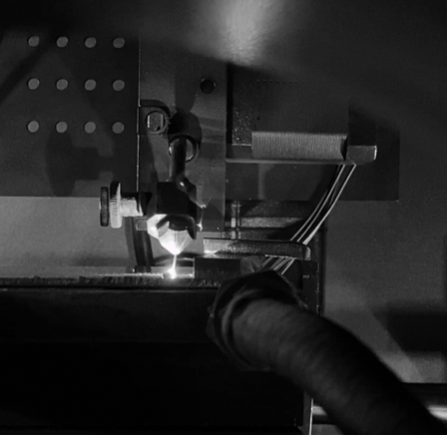

In-space additive manufacturing

Can you perform Metal AM in microgravity? Under vacuum and in -60°C?

When considering sustainable human existence in habitats or space stations, additive manufacturing (AM) of metallic spare parts and hardware is a major enabling technology. At the moment the most developed metal AM technique is SLM, which cannot be adopted for in-orbit manufacturing due to lack of sufficient gravity. To overcome this issue, we are developing a form feedstock and feeding system that can be operated in microgravity conditions.

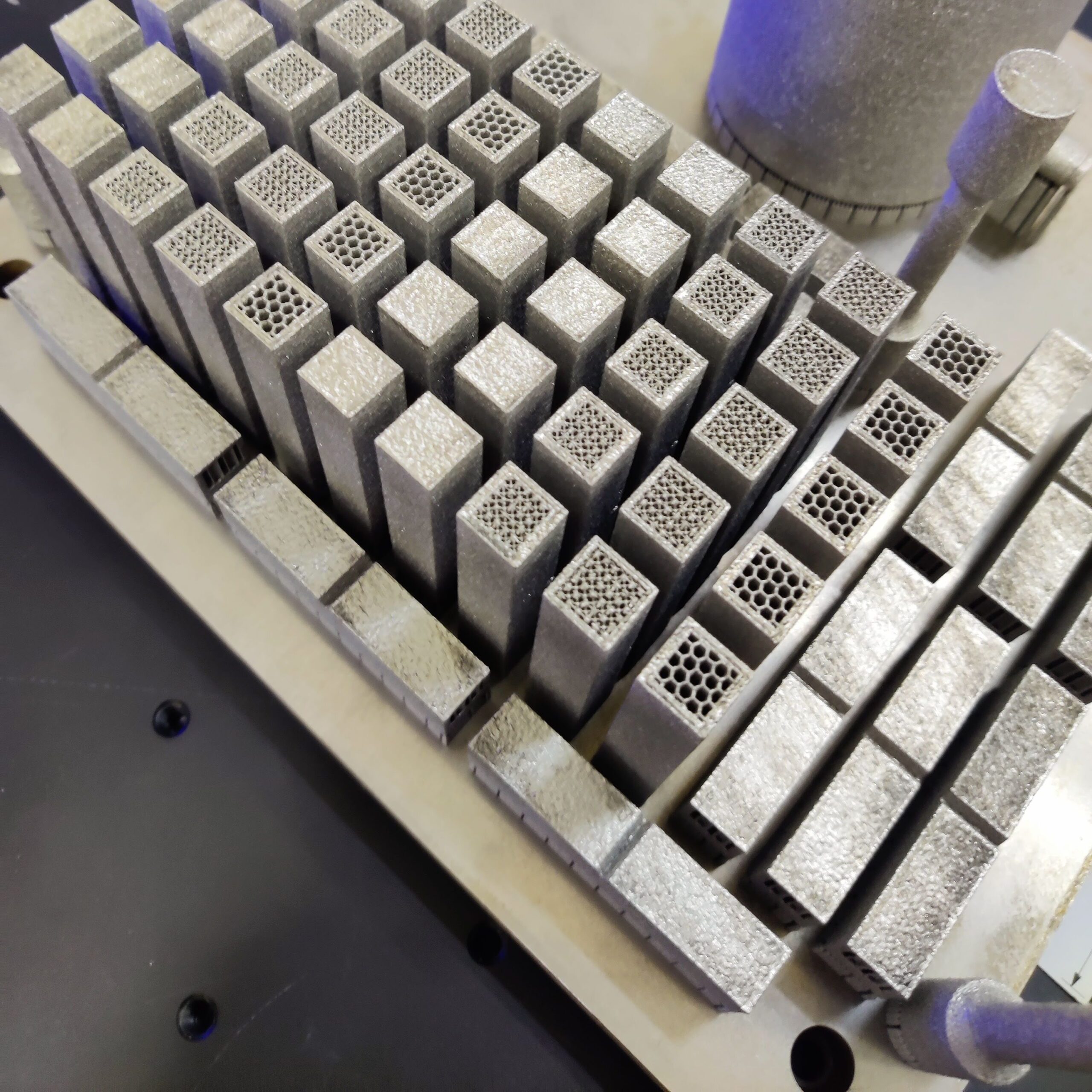

Additive manufacturing services

Metal additive manufacturing and so much more!

Materials: Ti-6Al-4V, AlSi10Mg, AISI 316L, 15-5PH, Inconel 718/625. Post Processing: 5-axis CNC machining, Laser & Arc welding, EDM - Cutting and Drilling, Heat treatment, HIP (Hot Isostatic Pressing), PVD coating, Shot blasting. Quality Control: VT / PT / MT / RT / UT, 3D Scanning, CMM Inspection, CT Scanning, Optical Profilometry, Optical Microscopy, SEM, (EDS/WDS/EBSD), TEM, Hardness Testing, Tensile testing, Impact testing, High pressure cycle testing, Outgassing testing, Helium leak testing